Article: Using casting process simulation to improve castings’ environmental footprint

2020-11-27

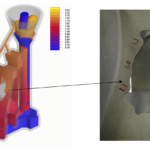

When a casting part is produced, a high amount of energy is generated since we need to melt the metal and then keep it at a high temperature during its filling into the mold cavity. This means that the production of a casting results in a big environmental footprint and high CO2 emissions during its manufacturing process. This footprint is inevitable but can be reduced by changing how you cast it.

This article will be focused on the possibilities to improve this and the use of casting process simulation to support the work.

Back to all news