The essence of casting simulation accuracy

NFO Drives is a Clean tech company who develops and manufactures products that make electrical motors for machines, fans and pumps etc more energy efficient. When they were re-designing components in one of their converters to improve performance and lower production costs the result was not entirely as expected.

NovaCast were contacted by NFO Drives since they had discovered distortion problems after their supplier’s test-produced the cooling backside of an inverter. The detail was designed based on mechanical properties, without taking into account the producibility.

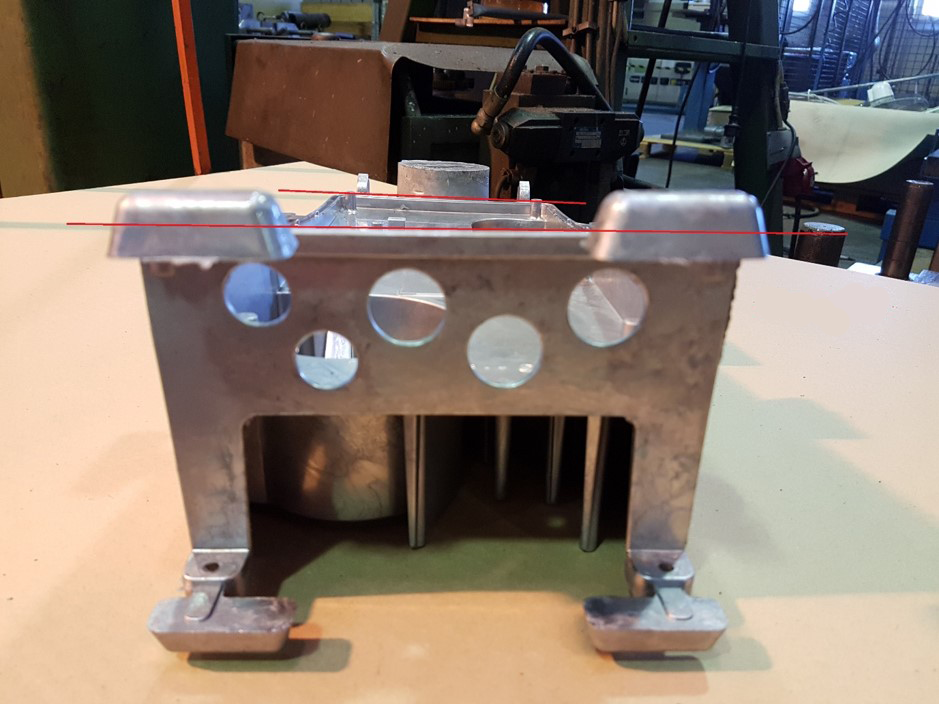

The aluminum casted detail with distortion problems.

Håkan Fransson, casting simulation expert at NovaCast:

”The first step was to simulate the casting detail in our simulation software package, NovaFlow&Solid. Our add-on module for predicting deformations, NovaStress, showed the extension of the distortion and the changes in measurement.”

The exact same casting issues showed while simulating the detail.

Håkan made ten iterations of the casting part; for example, he adjusted the flanges and added more ribs.

A few of the examples made.

Johan Braun, CEO at NFO Drives:

“This was the first time I saw a casting simulation program and it was impressive to see how accurate it was. It was great to find a solution and we learned that we should always simulate casting details before we decide upon the final construction.”