The efficiency of using NovaFlow&Solid

Scandicast SIA, located in Riga, Latvia, casts all standard material qualities in grey cast iron and ductile iron. On request they also produce modified special iron grades. Scandicast has been a NovaFlow&Solid customer since 2015.

Krišs Līdumnieks, Process Engineer at Scandicast, describes the process in their production, and the valuable use of our software NovaFlow&Solid:

”We produce various ductile iron castings, often in the form of ”ring” shapes, using grade 500-14. This grade presents significant challenges in managing shrinkage. To control solidification, we frequently utilize chills, as was the case with this casting.”

”We had already implemented solutions involving feeder application, chill usage, and gating design, similar to those used for other ”ring” castings. However, we observed shrinkage porosity at the junction of the feeder neck for this particular casting.”

”This was surprising initially, given the symmetric orientation of all feeders and the precise placement of chills between each feeder. One might expect uniform solidification with all four feeders functioning similarly.”

”However, examination of the feeders’ top piping revealed uneven solidification and filling. This prompted a deeper investigation, including flow and solidification simulations using NovaCast.”

”Initially, we validated our simulations by ensuring they accurately reflected the real-world conditions. The simulations indicated porosity at the feeder necks and different pattern of feeder piping. The last feeder to fill up is already with too cold metal and solidifies too fast, not compensating the shrinkage.”

”Subsequently, we engaged in engineering design work to develop a method to ensure simultaneous filling of the casting and all four feeders (as per the new simulation). Once the feasibility of this approach was confirmed through simulation, we conducted tests, which further affirmed its effectiveness.”

”As a result of these efforts, subsequent castings have been produced without encountering similar issues.”

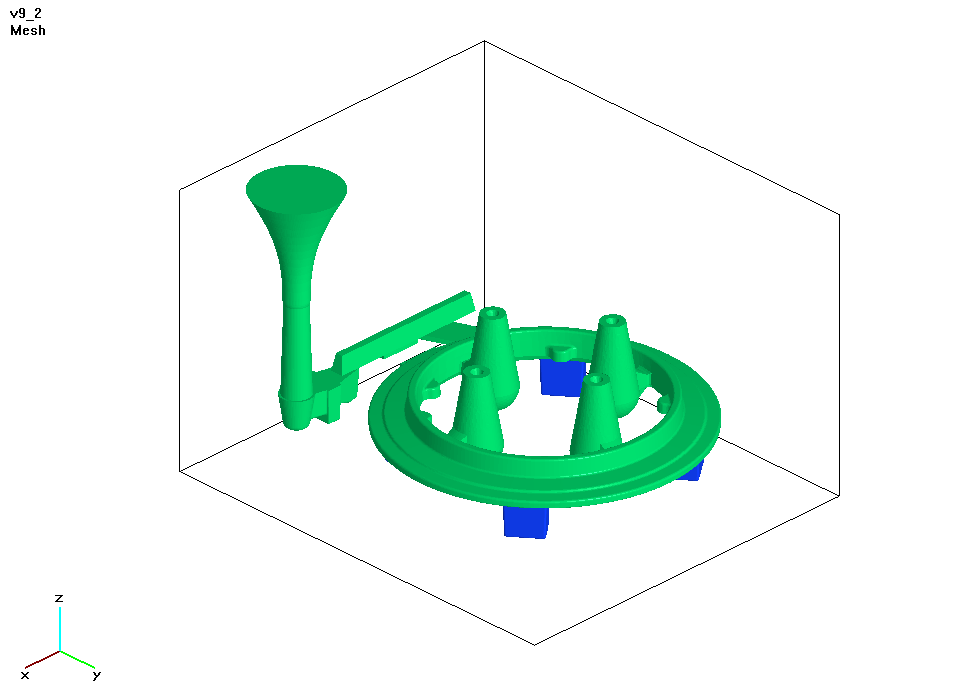

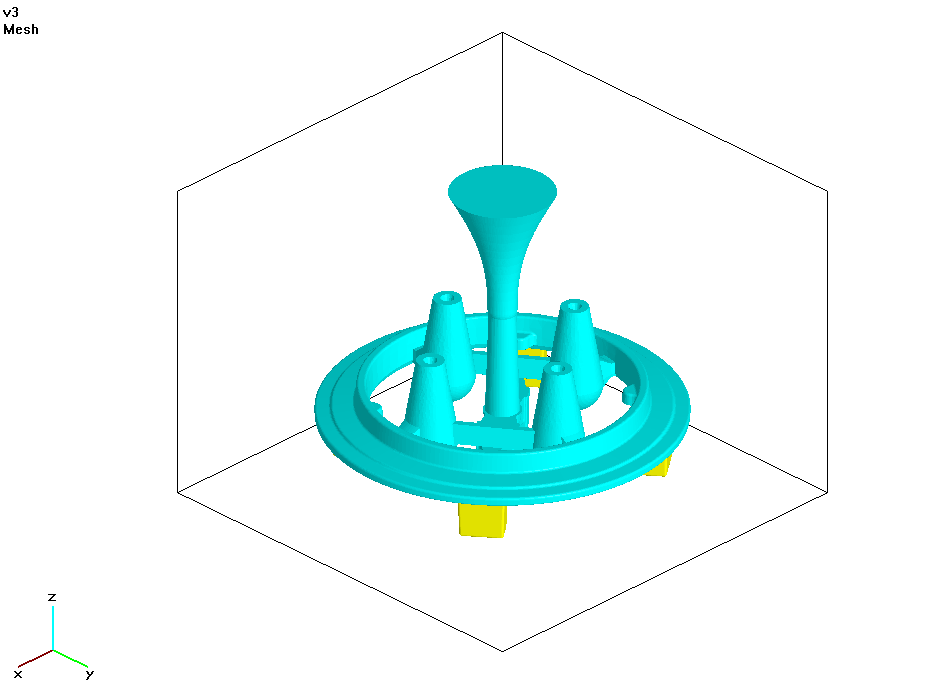

Old system. New system.

Actual approved result.