Customer Cases: Iron

Inserting ATAS MetStar data into NovaFlow&Solid

Thomas Dudley Ltd is a family owned and managed company that has been proudly manufacturing in the UK since 1920. Dedicated to quality, innovation and...

Chilling Fact: You Can Save Money by Thermal Analysis

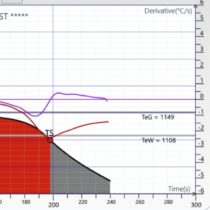

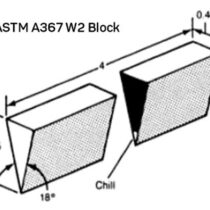

One very important effect of changing characteristics within the molten iron during induction furnace melting, revealed by thermal analysis, is the ch...

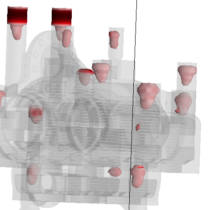

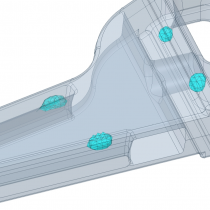

Predicting casting defects to control costs for robot molds

Since no-bake sand foundry Southern Cast Products (SCP) started simulating all casting parts, their efficiency has improved greatly. – There is ...

"One mold, one casting"

The award-winning patternmaker DMT’s main goal is to support the design and manufacturing of metal components using digital methods. With NovaFl...

Investing in ATAS MetStar

Our Slovenian customer ETA Cerkno invested in ATAS MetStar in the Fall of 2019 to ensure melt quality. ETA d.o.o. in Cerkno is the world’s largest man...

"ATAS MetStar reduces scrap rate by 30–40 %"

Turkey-based Demisas Döküm is one of the leading companies within iron casting production in the European foundry industry. For years, they had experi...

Improving precision and quality at Arizzi

Arizzi is an Italian foundry located in Albino. The company casts a large number of different products, from gear boxes, engine blocks and transmissio...

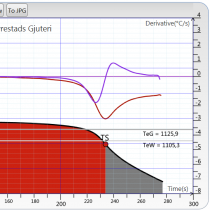

How Lyrestads get their perfect melt

Lyrestads foundry are a subcontractor founding cast iron for tool and machine manufacturers. A small part of their business is to make exclusive ornam...