Customer Cases: Aluminum

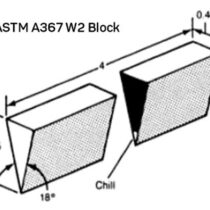

Chilling Fact: You Can Save Money by Thermal Analysis

One very important effect of changing characteristics within the molten iron during induction furnace melting, revealed by thermal analysis, is the ch...

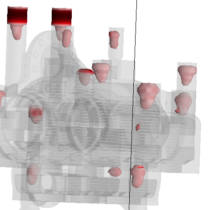

Predicting casting defects to control costs for robot molds

Since no-bake sand foundry Southern Cast Products (SCP) started simulating all casting parts, their efficiency has improved greatly. – There is ...

Designing castings for manufacturing as well as functionality

This customer case was originally initiated by Voxeljet. Since 2015, Brooks Crownhill Patternmakers (BCP) have been using NovaFlow&Solid as an agi...

"One mold, one casting"

The award-winning patternmaker DMT’s main goal is to support the design and manufacturing of metal components using digital methods. With NovaFl...

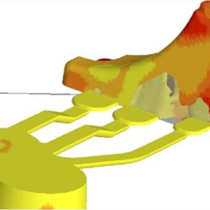

Going greener with NovaFlow&Solid

The use of lightweight materials is a permanently increasing need in the automotive industry. This is reflected in the growing use of this technology ...

Saving time and money with NovaFlow&Solid

In the Swedish town Floby, home to just over 1500 inhabitants, Automotive Components Floby (AC Floby) has resided for more than 60 years. From their f...

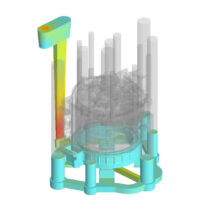

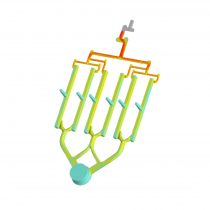

Instant simulation with NovaOne HPD

In the Summer of 2019 the newest member of our product range, NovaOne, was released. It is a quick and easy casting simulation software that will help...

The essence of casting simulation accuracy

NFO Drives is a Clean tech company who develops and manufactures products that make electrical motors for machines, fans and pumps etc more energy eff...

The success story of AB Lundbergs Pressgjuteri

About six years ago, the die-casting company AB Lundbergs Pressgjuteri chose to invest twofold when they hired their new tool manager Mattias Melin an...