ATAS MetStar

ATAS MetStar is an easy to use, adaptive metallurgical process control system for analyzing, stabilizing and optimizing the metallurgical production process. ATAS MetStar is the fundamental tool for a foundry to improve quality, control and increase stability of the metallurgical parameters. The result is reduced scrap rate, less energy consumption and a greener planet.

ATAS (Adaptive Thermal Analysis System) MetStar is a flexible metallurgical process control system for analyzing, stabilizing and optimizing the metallurgical production process. The system has been developed from a metallurgical point of view, based on years of foundry experience both from NovaCast’s own personnel but also customers’ day-to-day challenges. The system is used to create routines and rules for developing a lean production method.

The analyze phase consists of analyzing a number of physical samples of a specific alloy or melt quality and find the best practice. The stabilizing phase consists of extracting data from the analysis and defining the unique fingerprint for a specific desired quality to secure the best practice. The optimizing phase is the final stage of our process where fine tuning and improving the best practice takes place. This leads to a process with less variations and a stable quality and results in reduced scrap rate, less energy consumption and a greener planet.

ATAS MetStar predicts the possible risk for defects in the castings such as; micro shrinkage porosity, macro shrinkage porosity, chill tendency (cementite), inverse chill tendency, oxygen content and mechanical properties.

>> One of the latest news in ATAS MetStar version 10.4 (released on November 8, 2023) is Enhanced MasterMind

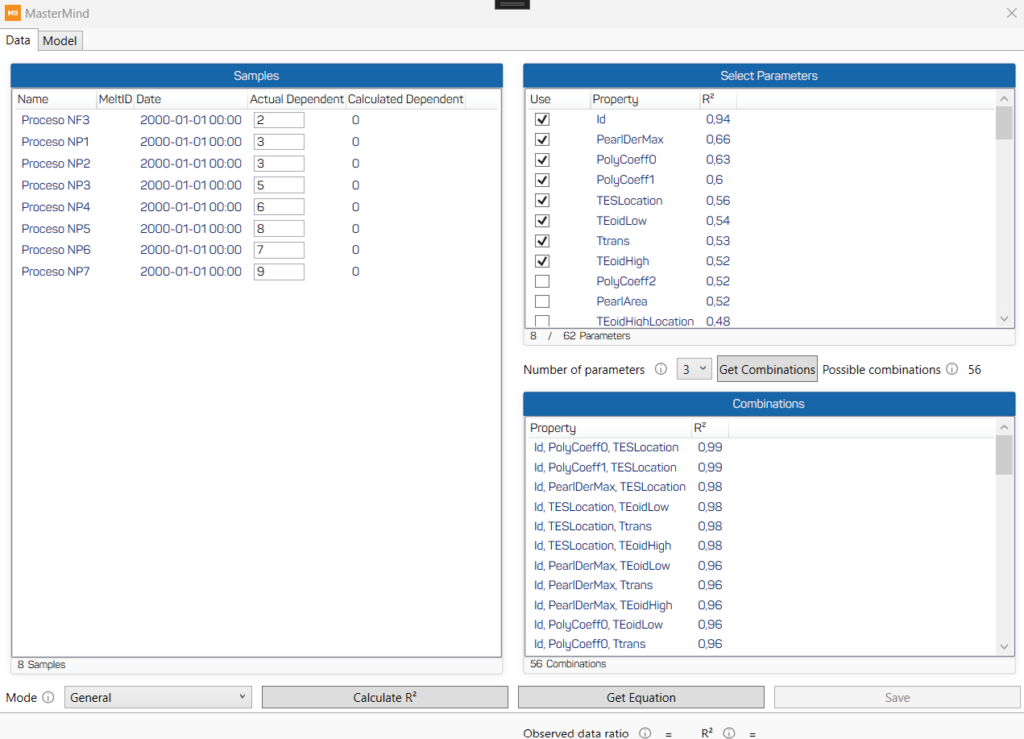

MasterMind has been a part of ATAS MetStar for a few years now and it has allowed users to find correlations between thermal analysis parameters and anything imaginable, if they exist. MasterMind has shown the correlation between each individual parameter and parameter we are hoping to predict, but sometimes the best combination of parameters is not the parameters with the best correlation individually as those parameters themselves could have some correlation and adding more of the same will not improve the prediction. For that reason, we have now added a possibility to find the best combination out of given number of parameters. This will greatly help in finding the optimal equation for a new parameter, if there is one.

We have also now included many more parameters to be calibrated within ATAS MetStar, such as CTL and ACEL. On top of that, we have improved the usability of the module and added more tooltips to help even the beginner to the going on it.

Click to enlarge.

In the new ATAS MetStar 10.4 version we have also added the following:

- Pearlite evaluation modified.

- Enhanced MasterMind.

- Morphological Index. This new parameter will help establish where you are in the Hypo/Eutectic/Hyper range.

- Spectrometer Connection usability.

- Curve Comparison has a completely new look including customizable gauges.

- Added new CEL-equation based on literature review (Prof. Doru Stefanescu).

- Including TEGray into optimized CEL-target based on modulus.

- Alloy templates portfolio has been expanded.

- Increased visibility of No Alloy Selected.

- Increased Visibility of new Spectrometer samples.

>> Are you a student?

Click here to learn more about our university offer.

In need of a charge calculation system?