Article: Simulating high pressure die casting with full process

Written by Håkan Fransson, Technical Manager simulation at NovaCast

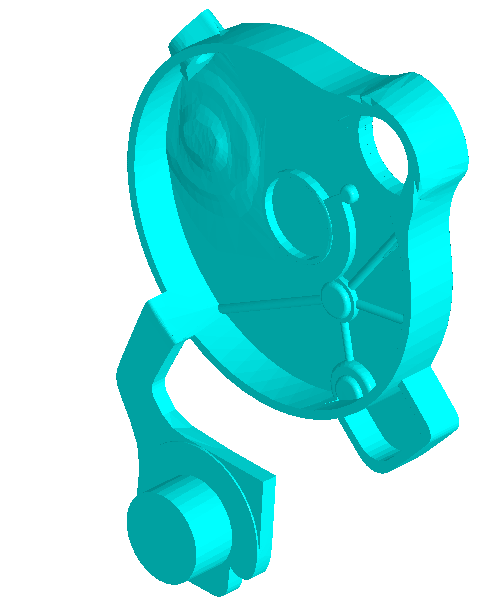

Biscuit simulations

Historically, most simulations of high pressure die casting process have been done with the so called ”biscuit” method. The ”biscuit” method means that you are not simulating the whole process but only the shot (casting + ingate system + the biscuit) meaning that filling starts at the point where the biscuit begins. This is of course a simplification that makes the simulation less accurate. The reasons for making simulations like this are:

Historically, most simulations of high pressure die casting process have been done with the so called ”biscuit” method. The ”biscuit” method means that you are not simulating the whole process but only the shot (casting + ingate system + the biscuit) meaning that filling starts at the point where the biscuit begins. This is of course a simplification that makes the simulation less accurate. The reasons for making simulations like this are:

1. Computer memory – A full process would need too much calculation elements and thus too much memory that we did not have in a normal computer. The full process adds 300 – 800 mm calculation elements in x or y direction because of the length of the chamber.

2. Calculations took too long time to be practical with a full process.

3. Many simulation programs could not properly simulate piston movement 5 years ago.

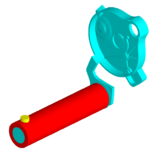

Piston movement simulations

When it became possible to practically make full process simulations (which means gravity filling of chamber followed by piston movement) for high pressure die casting simulations, we instantly noticed the following:

1. We could more accurately investigate the effect of different velocities and switch points since they now were set by millimeter piston movement instead of time or trigger points. Also possible waves were detected that could potentially enclose air.

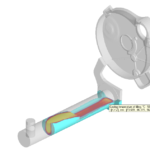

2. Most simulation engineers have used too high pouring temperatures for their ”biscuit” simulations. We discovered this when we started to simulate the full process with chamber filling and piston movement that the temperature drop were significantly higher than we thought. We noticed temperature drop in the chamber of up to 100°C and in some cases also over 100° This was later also verified at different foundries by thermocouple readings. We also found the same temperature drop in a project by the Swedish Foundry Association.

3. Gas bubbles are created both during gravity filling of the chamber but also by the piston movement. These bubbles continues in to the casting and contributes to the gas porosities in the casting.

4. Effect of too high or too low filling ratio in the chamber could be studied. For example a very low filling ratio results in high amount of solification percent during the filling of the chamber.

Furthermore, NovaFlow&Solid is using something called Multi-mesh which means that we can use different size of mesh for the whole calculation domain during certain times in the simulation making it possible to simulate the gravity pouring of chamber followed by the piston movement in just a few minutes. In this way you can concentrate the simulation time on the most important part of the simulation; the filling of the casting cavity.

Webinar

In June 2020, we presented a webinar (hosted by Altair) together with Johannes Jerg at Jerg Engineering adressing exactly this part of the simulation process namely the piston movement simulation. Fill in the form below if you are interested in the recording.